Premier Aluminum Llc - Questions

Premier Aluminum Llc - Questions

Blog Article

All About Premier Aluminum Llc

Table of ContentsThe Best Guide To Premier Aluminum LlcThe Definitive Guide to Premier Aluminum LlcThe Best Strategy To Use For Premier Aluminum LlcA Biased View of Premier Aluminum LlcThe Facts About Premier Aluminum Llc Uncovered

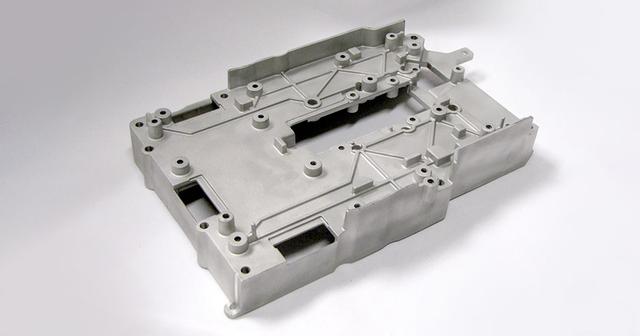

When selecting a light weight aluminum factory for your manufacturing needs, it's crucial to examine a number of variables. One of the most vital elements to think about is the experience and competence of the factory. Selecting a shop who has the ideal expertise of the light weight aluminum spreading procedure, and the profile to reveal for it, aids to have a successful result for your job.Having the experience and market knowledge to engineer your castings for optimum production and high quality end results will certainly streamline the task. Making light weight aluminum castings requires a complex set of processes to accomplish the appropriate outcomes. When choosing a brand-new light weight aluminum factory to companion with, ensure they have substantial sector experience and are well-informed about all facets of the light weight aluminum spreading procedure: layout, manufacturing, material analysis, and item testing.

The factory must likewise have a proven performance history of supplying exceptional items that meet or exceed client assumptions. Quality assurance needs to additionally go to the top of your checklist when selecting an aluminum foundry. By working with a qualified shop that complies with the requirements for quality assurance, you can safeguard the honesty of your item and guarantee it meets your specifications.

Some Known Factual Statements About Premier Aluminum Llc

Numerous components that extremely complicated forms can be produced utilizing this procedure. Prior to you begin browsing for a trusted aluminum die wheel, there are some important points that you require to do.

You have to ask on your own what kind of light weight aluminum pass away castings you need. After determining what you call for, you need to specify the specifications of the aluminum pass away castings you need. Figure out the weight, thickness, size, and various other specifications of the light weight aluminum die-cast you require. It would certainly also be a lot far better if you could draw and reveal all the measurements of the light weight aluminum die-cast.

After having this details, you can start investigating aluminum die-casting suppliers. You can do this by simply inputting the keyword" Light weight aluminum die casting producers" on the Google search engine.

Some of the concerns you require to ask on your own are whether they have actually experienced and trained drivers, the length of time their company has been in operation, or if they have some accomplishments. You can commonly obtain the response to these questions from the supplier's website. You can investigate various other websites or outside sources to verify if the info offered on the manufacturer's site is authentic.

The Of Premier Aluminum Llc

An additional thing you have to take into consideration is the maker's capability to create light weight aluminum die-casting items. In other words, the quantity of items the supplier can produce at an offered time. Some of the important questions you require to ask on your own are whether the maker can create a higher volume or can the supplier satisfy your demands.

(https://garymartin53403.wixsite.com/my-site-1/post/top-aluminum-casting-company-premier-aluminum-llc)What if your business requires 10,000 items of specific maker parts from the maker within one month? You got this amount; however, the maker can only create 5000 items of these machine parts within one month (Casting Foundry). Because of this, you will not be able to obtain the amount that you order on schedule

The Best Strategy To Use For Premier Aluminum Llc

Thus, it is necessary that you ought to ask if the maker is carrying out an internal tooling procedure. In addition, you need to ask the manufacturer how much Learn More Here the price of internal tooling is. The in-house tooling process, which permits you to create distinctive layouts and forms can be an extra price.

This element straight correlates with the maker's manufacturing capability. You need to seek a producer that can guarantee quicker delivery of products. This need to be done in such a means that high-quality criteria are maintained. This can guarantee that you can obtain your items in a timely manner, and you can prevent missing out on those important service chances.

This suggests that there are numerous options that you can pick from. That is why it is considerably suggested that you need to pick a manufacturer that can generate different kinds of light weight aluminum die-cast products.

Premier Aluminum Llc Can Be Fun For Everyone

Frequently, these light weight aluminum die-casting products will certainly call for some decors, machining, or finishing touches. Having this in mind, you ought to search for a producer that can carry out a range of additional finishing jobs when die spreading is done. Some examples of completing operations include Chromating, CNC Machining, Sandblasting, Powder finish, Anodized, E-coating, Damp paint, Plating, and much more.

Die casting is one of one of the most cost-effective, accurate, and protean production procedures on the planet minute. The procedure involves fitting molten significance, under pressure, into an applicable die (planet), and previously strengthened it can be expelled and finished (if necessary) in a range of means. The dies are [...]. Report this page